In 1930, Vladimir Lukianov was an engineer with the Central Institute of Railway Engineers in Moscow. There, he worked to calculate the temperatures in concrete structures, which was essential to preventing cracks in concrete structures and earthworks. At that time, methods of calculation couldn’t provide the quick, accurate solutions they required, and they relied on too many assumptions. Lukianov invented a device that he named the Hydraulic Integrator to mechanize transient calculations. This device was unique in that replaced gears with water. In other words, it was the world’s first “water computer.”

In 1949, the Moscow Plant of Calculating Machines put the Hydraulic Integrator into production, and was even imported. It was used in the construction of a wide variety of buildings, such as power plants, and applied to many branches of science, including physics, metallurgy, and rocket science. Amazingly, this device remained in use until the 1990s.

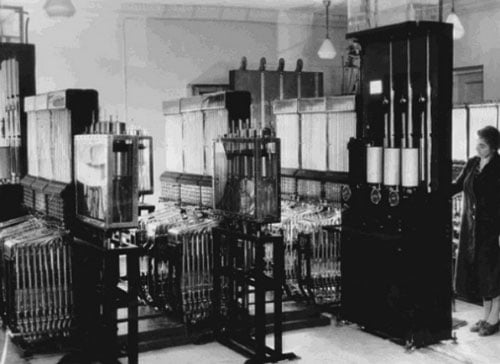

Hydraulic Integrator of Vladimir Lukianov

Vladimir Sergeevich Lukianov (Владимир Сергеевич Лукьянов) was born in Moscow, on 17 March 1902, in the family of an insurance agent. In 1919 he graduated from a Moscow classical high school and entered the building department of the Moscow State University of Railway Engineering. He graduated in 1925 and was sent to build the railroads Troitsk — Orsk, and Kartaly — Magnitnaia. After working for five years on the construction and design of railways, in 1930, Lukianov went on research activities at the Central Institute of Railway Engineers in Moscow, where he worked on the calculation of temperatures in concrete structures.

To ensure the quality and durability of concrete structures, earthworks and concreting were carried out only in the summer, but the cracks in the structures were not always able to be avoided. Lukianov decided to explore the possibility of carrying out construction work in the wintertime and find out the reasons for the destruction of concrete structures.

He began to study temperatures in concrete cells, but current methods of calculation could not provide quick and accurate solutions to complex differential equations that describe the temperature, and the analytic solution required many assumptions.

Searching for a new approach to the problem, Lukianov applied the method of analogies between different physical processes, and in 1934 proposed a fundamentally new way of mechanization of transient calculations — the method of hydraulic analogies. The result was the creation of a kind of model of thermal processes — the so-called Hydraulic Integrator.

The first model (one-dimensional) of the Hydraulic Integrator was created in 1936, the so-called ИГ-1 (Интегратор Гидравлический 1). It was a primitive device made of roofing iron, tin, and glass tubes, but it successfully resolved the problem of investigating the concrete temperature regimes. Moreover, it was the world’s first water-driven calculating machine, as well as the first computer for solving differential equations in partial derivatives.

Its main node is vertical (main) vessels of sizable capacity (in the right part of the upper photo, in front of the operator), interconnected by means of tubes with variable hydraulic resistance and connected to moving vessels. By raising and lowering them, the operator can change the water flow in the main vessels. The start or stop of the process of the calculation is made by means of cranes with common control.

Solving a problem using the Hydraulic Integrator needed some preparation:

1. Create a design scheme for the test process

2. On the basis of this scheme produce a compound of vessels to identify and choose the values of hydraulic resistances of the tubes

3. Calculate the initial values of the quantity to be searched

4. Draw a graph of the external conditions of the simulated process

After the preparation steps, the operator should set the initial values: fixed and mobile cranes in closed vessels must be filled with water to the calculated levels and then noted on graph paper attached for piezometers (measuring tubes)—It turns out a kind of curve. Then all the valves must be opened simultaneously, and the operator must change the height of moving vessels in accordance with the schedule of changes in the external conditions of the simulated process. At the same time, the water pressure in the main vessels was changed by the same law as the temperature. The liquid level in the piezometers changed, and at the right time valves must be closed, stopping the process, and graph paper will mark a new level position. These marks have to be plotted, which will be the solution.

In 1941 Lukianov constructed a two-dimensional version of the Hydraulic Integrator. In the 1940s the machine was put into production in the Moscow Plant of Calculating Machines. When in 1949 was established the State Institute for Calculation Machines, the Hydraulic Integrator was one of the first calculating machines put into series production and was even exported. The Hydraulic Integrator was successfully used in the construction of power plants, mine buildings, geology, thermal physics, metallurgy, rocket science, and many other areas. In the middle 1970s, Hydraulic Integrators were still used in over 115 productions, and scientific and educational organizations in the USSR and abroad, and remained in use up to the 1990s.

The Hydraulic Integrator of Vladimir Lukianov (© Moscow Polytechnic Museum)

Two Hydraulic Integrators of Vladimir Lukianov are currently presented in the collection of analog machines of the Moscow Polytechnic Museum (see the upper image).

Vladimir Lukianov was a professor and doctor of technical sciences and a holder of the State (Stalin) Award of 1951. He died in 1980 in Moscow.

The image featured at the top of this post is ©Unknown author / public domain